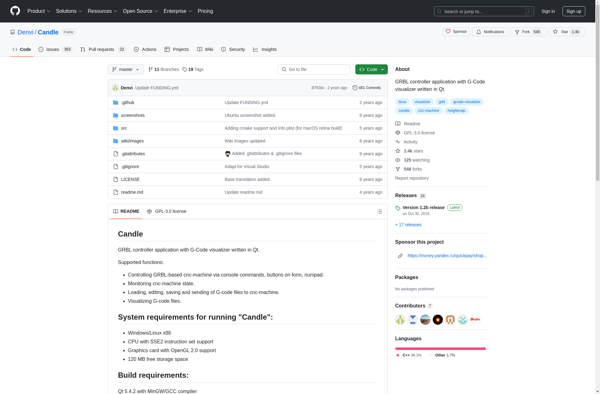

Description: Candle is an open-source remote pair programming application that allows developers to collaborate in real-time on code. It enables shared editing, video chat, and terminal access between peers.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: Ultimate CNC is computer numerical control software used for controlling CNC machines like mills, lathes, routers, and laser cutters. It offers an intuitive interface for designing and machining parts.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API