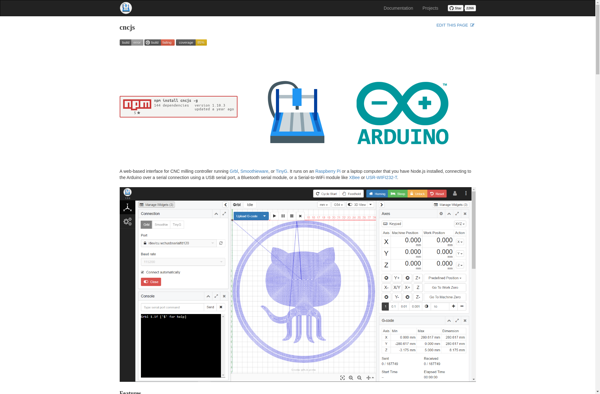

Description: CNCjs is an open-source web-based CNC control software that allows you to control CNC machines from a web browser. It can send G-code commands to CNC machines like 3D printers, laser cutters, CNC routers, and milling machines.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: PlanetCNC is an affordable and easy to use CAD/CAM software for CNC machining. It allows you to design parts and toolpaths for milling, turning, plasma and laser cutting. Great for hobbyists and small manufacturing shops.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API