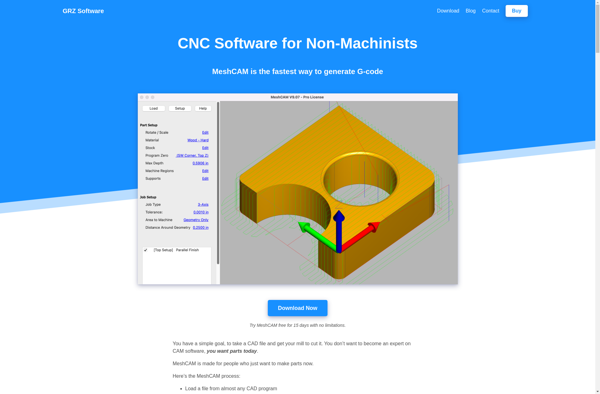

Description: MeshCAM is 3D machining software designed for CNC machining applications. It allows users to import and prepare 3D models for fabrication with tools like multi-axis milling machines. Key features include efficient roughing and finishing toolpaths, simulation, and support for common CAD file formats.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: Mastercam is computer-aided manufacturing (CAM) software used for programming computer numerical control (CNC) machine tools. It allows users to design parts, generate toolpaths, visualize machining operations, and simulate CNC code.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API