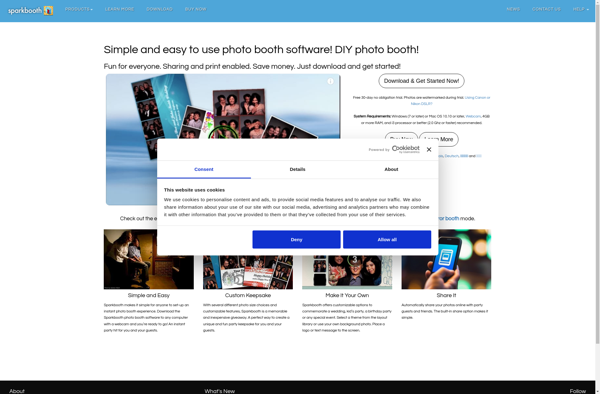

Description: Sparkbooth is a photo booth software that allows you to set up an automated, self-service photo booth. It includes features like unlimited photo captures, customizable templates and layouts, image filters, green screen effects, animated gifs, social media sharing options, and more.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: CamStar is a manufacturing execution system (MES) software designed for electronics manufacturers. It helps track production flows, materials, quality, and provides manufacturing analytics and intelligence.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API