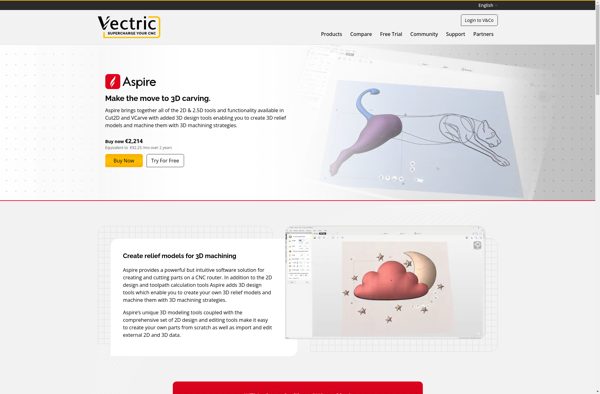

Description: Vectric Aspire is a powerful software for designing and machining parts on CNC routers and mills. It allows users to create 3D models and 2D vector artwork, generate toolpaths, preview machining operations, and send code to CNC machines.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: Mastercam is computer-aided manufacturing (CAM) software used for programming computer numerical control (CNC) machine tools. It allows users to design parts, generate toolpaths, visualize machining operations, and simulate CNC code.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API