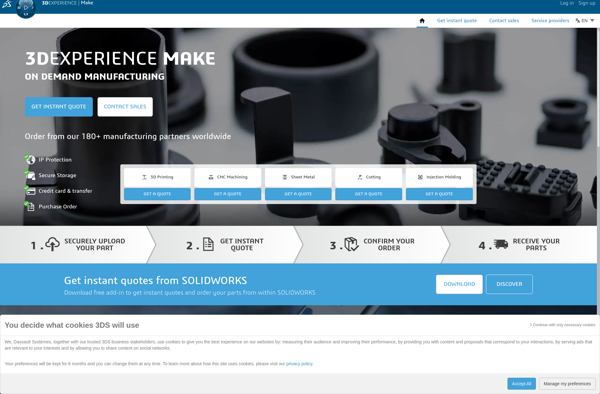

Description: 3DEXPERIENCE Make is a comprehensive and integrated development environment for manufacturing design. It provides tools for entire product development including CAD, simulation, manufacturing preparation, and more. It aims to streamline product design and accelerate development.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

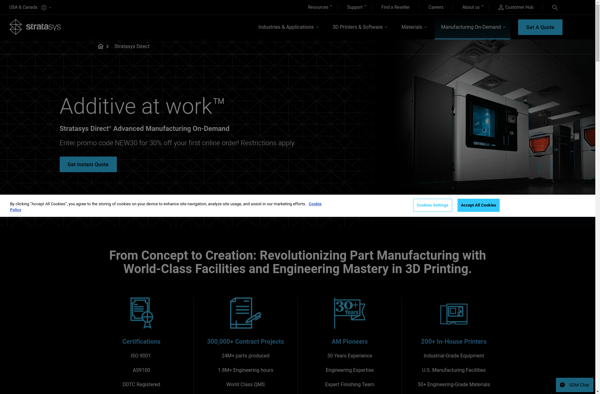

Description: Stratasys Direct Manufacturing is a 3D printing service bureau focused on rapid prototyping and low-volume production. They offer Fused Deposition Modeling (FDM), PolyJet, and Stereolithography 3D printing technologies to produce functional prototypes, end-use parts, and production-grade injection molds.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API