Description: CamBam is CAD/CAM software designed specifically for CNC machining. It allows users to easily design parts and create toolpaths for CNC mills and lathes. CamBam supports 2D and 3D CAD design and includes features like customizable post-processors and toolpath simulation.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

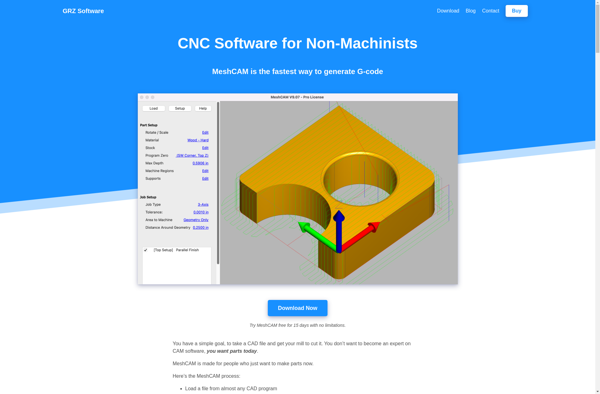

Description: MeshCAM is 3D machining software designed for CNC machining applications. It allows users to import and prepare 3D models for fabrication with tools like multi-axis milling machines. Key features include efficient roughing and finishing toolpaths, simulation, and support for common CAD file formats.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API