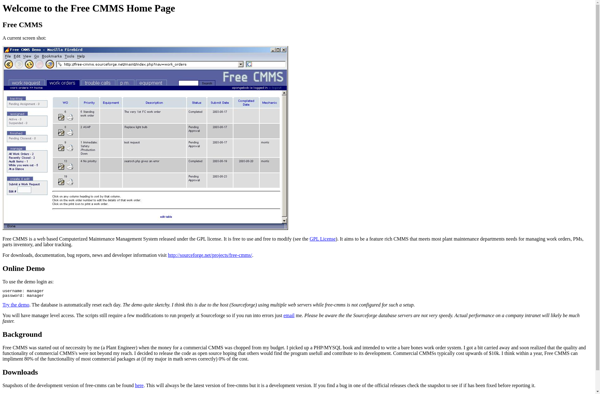

Description: A free computerized maintenance management system (CMMS) is software that helps organizations track and organize maintenance operations. It provides features like asset management, work order scheduling, inventory control, preventative maintenance planning, without any licensing costs.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: Lena Maint CMMS is a cloud-based computerized maintenance management software designed for small and midsize businesses. It allows users to schedule and track maintenance tasks, manage assets and inventory, record downtime and failures, optimize preventive maintenance plans, and generate reports.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API