Description: Optimumcut is a software for optimizing cuts from panels, minimizing waste. It allows users to set parameters and requirements, and then calculates the optimum arrangement of parts.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

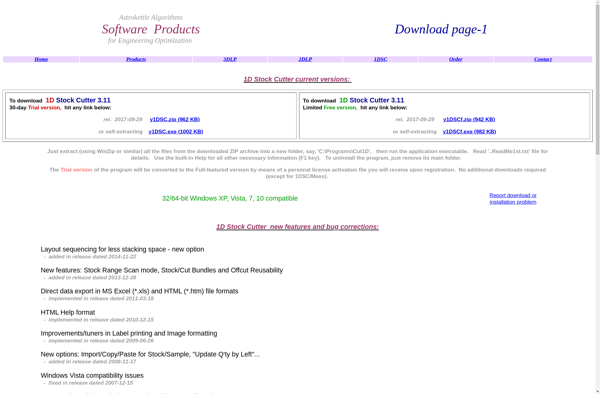

Description: 1D Stock Cutter is a software for optimizing material usage and reducing waste when cutting linear stocks, boards, glass, etc. It features an intuitive drag-and-drop interface to quickly arrange cutting patterns.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API