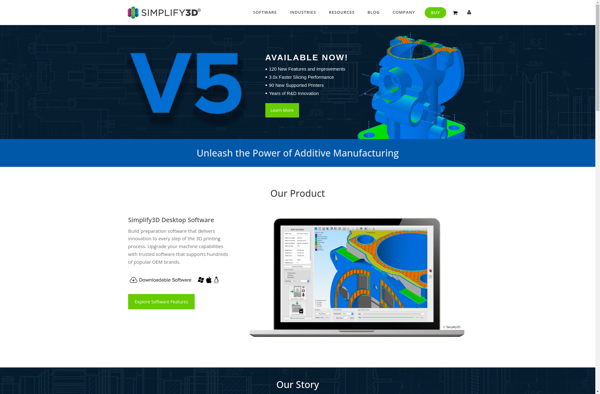

Description: Simplify3D is a slicing software used for 3D printing. It allows advanced customization and optimization of print settings to improve print quality and precision. Simplify3D works with most desktop 3D printers.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: KISSlicer is a free, open source slicer application for preparing 3D print files. It allows users to orient, scale, and slice 3D models to generate G-code for printing on FDM 3D printers.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API