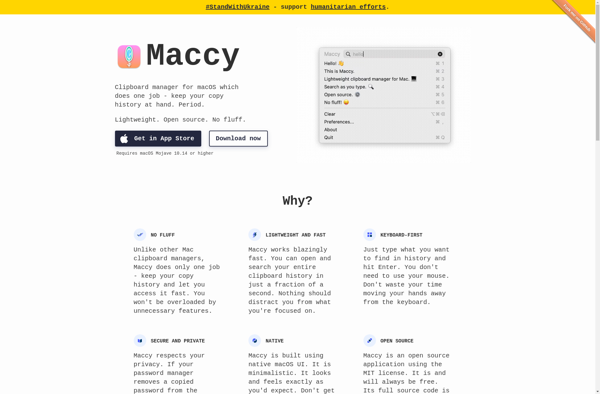

Description: Maccy is a lightweight clipboard manager for macOS. It allows you to easily access your clipboard history and quickly paste from it. Useful for copying and pasting frequently used items.

Type: Open Source Test Automation Framework

Founded: 2011

Primary Use: Mobile app testing automation

Supported Platforms: iOS, Android, Windows

Description: Klipper is an open-source 3D printer firmware. It communicates with software on the host computer using a serial connection. Klipper focuses on high-precision control of stepper motors and operates on a microcontroller close to the printer hardware.

Type: Cloud-based Test Automation Platform

Founded: 2015

Primary Use: Web, mobile, and API testing

Supported Platforms: Web, iOS, Android, API