ControlNet

ControlNet is an industrial automation software that allows users to monitor, control, and optimize industrial processes through a single platform. It connects devices, controllers, sensors, etc. across an industrial network.

ControlNet: Industrial Automation Software

Monitor, control, and optimize industrial processes through a single platform, connecting devices and controllers across an industrial network.

What is ControlNet?

ControlNet is an industrial automation software designed to monitor, control, and optimize complex industrial processes. It provides a single unified platform to connect and integrate devices, controllers, sensors, etc. across an industrial control network.

Some key features of ControlNet include:

- Real-time data collection and analytics - Acquires data from connected devices and applies analytics to turn it into actionable insights about the production process.

- Centralized control and supervision - Enables centralized and remote monitoring and control of devices spread across the plant floor.

- Alarm notifications - Detects faults or deviations and sends out notifications to operators.

- Reporting and trend analysis - Generates historical reports and trends for optimizing processes.

- Open connectivity - Supports connectivity and interoperability between devices from different vendors using open communication standards.

- Scalability - Modular architecture allows the system to scale up as per changing needs.

- Redundancy and high availability - Ensures critical industrial control activities are unaffected during component failures.

- Regulatory compliance - Helps plants maintain compliance with safety and reporting regulations.

ControlNet improves productivity, flexibility, asset utilization while reducing downtimes in industrial automation environments. It is used across industries like oil and gas, energy, pharmaceuticals, automotive, FMCG, etc.

ControlNet Features

Features

- Remote monitoring and control of industrial processes

- Centralized data collection and visualization

- Alarm management and notification system

- Trend analysis and reporting

- Integration with various industrial protocols and devices

- Customizable user interfaces and dashboards

- Mobile app for remote access

Pricing

- Subscription-Based

Pros

Comprehensive industrial automation solution

Improved operational efficiency and productivity

Centralized control and visibility of industrial processes

Scalable and flexible to accommodate growing needs

Reduced maintenance and downtime through remote monitoring

Cons

Complexity may require specialized training for users

Potential integration challenges with legacy systems

Ongoing maintenance and software update costs

Dependency on a stable network connection for remote access

Official Links

Reviews & Ratings

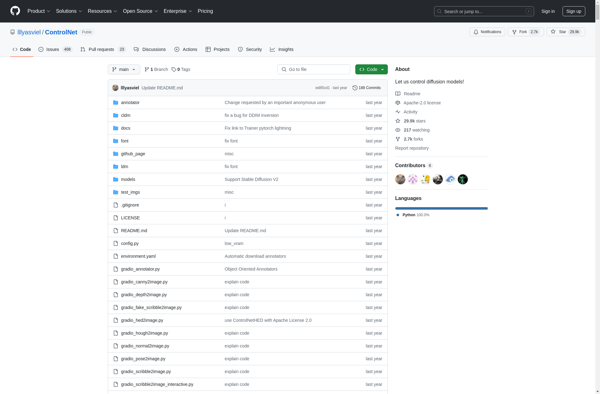

Login to ReviewThe Best ControlNet Alternatives

Top System & Hardware and Industrial Automation and other similar apps like ControlNet

Here are some alternatives to ControlNet:

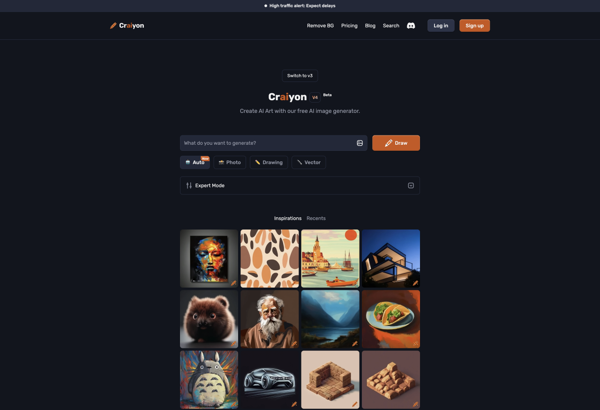

Suggest an alternative ❐Craiyon

Craiyon (formerly DALL-E mini) is an AI image generator that creates images from text descriptions. It uses a deep learning model trained on millions of image-text pairs to generate highly realistic and creative images from natural language prompts.Some key things to know about Craiyon:It was created by Anthropic, an AI...

DALL-E 3

DALL-E 3 is a state-of-the-art AI system capable of generating realistic and creative images from a text description. It was created by the AI safety startup Anthropic and builds on OpenAI's earlier DALL-E models.Users can give DALL-E 3 a text prompt and it will generate novel images that match the...

Midjourney

Midjourney is an artificial intelligence system that generates images from text descriptions. It utilizes a deep learning model called DALL-E that has been trained on millions of image-text pairs to understand the relationship between language and visual concepts.Users can provide Midjourney with a text prompt such as "an oil painting...

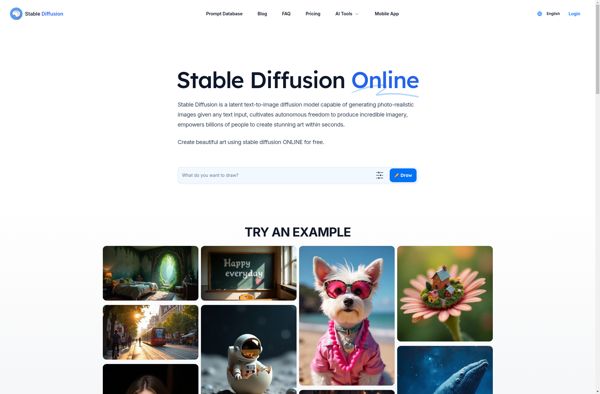

Stable Diffusion Online

Stable Diffusion Online is a free web application powered by the Stable Diffusion AI image generator model. It allows anyone to create AI-generated images just by typing a text description of what they want the image to depict. Stable Diffusion Online provides an accessible way for artists, designers, developers and...

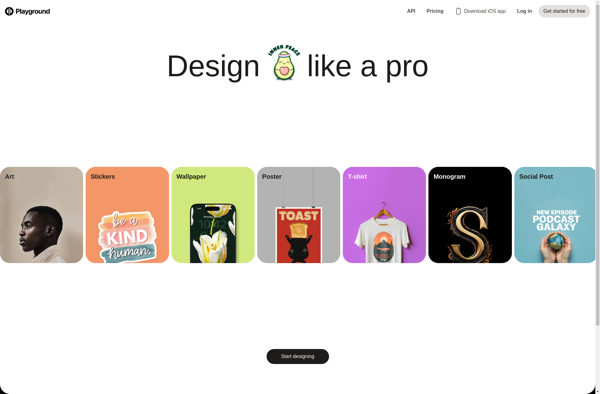

Playground AI

Playground AI is an artificial intelligence-powered conversational agent developed by Anthropic to be helpful, harmless, and honest. It is designed to have natural conversations on a wide range of topics while avoiding potential harms.Some key features of Playground AI include:Conversational ability - It is skilled at having open-ended discussions on...

Twogether AI

Twogether AI is an artificial intelligence-powered conversational agent developed by Anthropic to be helpful, harmless, and honest. It is designed to have natural conversations with humans and provide useful information on a wide variety of topics.Some key features of Twogether AI include:Natural language processing abilities to understand questions and context...

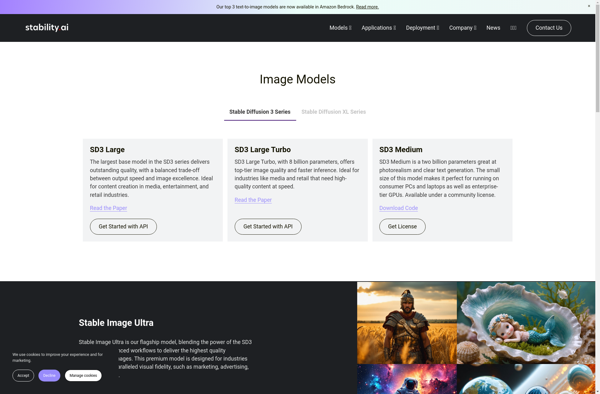

Stable Diffusion XL

Stable Diffusion XL is an enhanced version of Stable Diffusion, the open-source AI image generator that took the world by storm in 2022. Developed by Stability AI, Stable Diffusion XL pushes the boundaries of what's possible with text-to-image diffusion models.At the core of Stable Diffusion XL is an upgraded model...

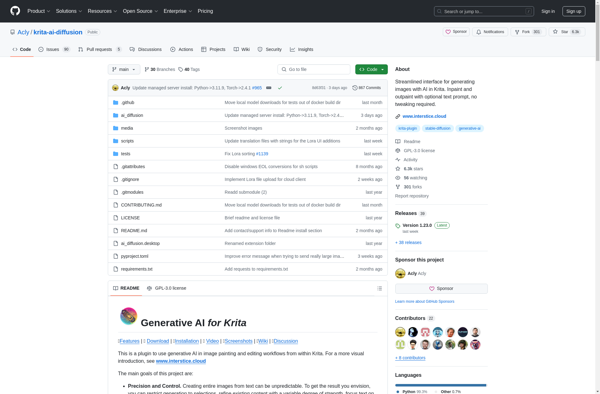

Krita AI Diffusion

Krita AI Diffusion is an open-source digital painting and illustration application designed for concept artists, matte and texture artists, illustrators, and VFX artists. It combines the features of Krita, a popular free and open source painting program, with AI diffusion technology to assist in the creative process.The AI diffusion features...

BlueWillow

BlueWillow is a comprehensive cloud-based project management software designed specifically for creative teams and marketing/advertising agencies. It provides a complete set of tools to help creative teams plan projects, manage tasks and deadlines, track time and budgets, allocate resources, facilitate collaboration among team members, and generate reports.Some of the key...

InvokeAI

InvokeAI is an artificial intelligence-powered virtual assistant designed to help users be more productive and efficient. It uses natural language processing to understand commands and requests typed in plain English and responds with relevant information or automates tasks.Key features of InvokeAI include:Natural language understanding - Understands free-form English questions, commands...

Noiselith

Noiselith is an audio synthesis and algorithmic music composition application developed by Mark Harrop. It focuses on the generative and automated creation of sounds, rhythms, and musical structures using mathematical models and controlled randomness.At its core, Noiselith functions as a modular virtual synthesizer with components like oscillators, filters, and envelopes....

Stable Diffusion AI

Stable Diffusion is an AI image generation tool that is powered by neural networks and self-supervised deep learning. It was created by researchers at the AI startup Stability AI and released under a Creative Commons license in August 2022.Stable Diffusion can generate realistic images and artwork from text prompts. It...

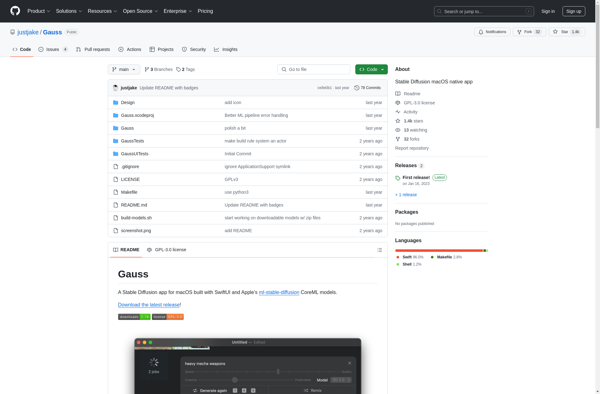

Gauss

Gauss is an open-source data analytics and machine learning platform developed by Huawei. It provides a comprehensive set of tools for working with data including:Data integration and transformationExploratory data analysis and visualizationMachine learning model development, evaluation, and deploymentDistributed computing and scalabilitySome key capabilities and benefits of Gauss include:Supports the complete...